Gas-Fired Combustion Appliances

Gas-Fired Combustion Appliances

This scope of this section is limited to the safety of the inspector during the inspection of the heating system. It is not meant to cover in detail proper inspection methods of various heating systems.

The primary danger from heating systems is related to their fuel source. This may be a gas, such as propane or natural gas, heating oil, or electricity.

Gas-fired combustion appliances are heating appliances that produce heat through combustion using natural gas or propane as a fuel. Typically, these are furnaces, boilers and water heaters.

Pre-Ignition

The most serious danger to persons inspecting gas-fired combustion appliances is pre-ignition.

“Pre-ignition” is a strange term, considering that ignition is actually delayed. Upon receiving a call for heat from the thermostat, gas flows into the burn chamber, but, for a variety of possible reasons, ignition is delayed, so when ignition finally takes place, an excessive amount of gas has accumulated in the burn chamber, resulting in an explosion.

The resulting explosion may be small and contained within the burn chamber, or if enough gas has accumulated, the flame may roll out into the room. If an inspector is on his knees looking into the burn chamber to evaluate the condition of the burner flame, the result can be singed hair and eyebrows, or worse. The bodily harm from the ignition explosion can range from injury to the ears or one’s hearing due to exposure to the loud noise, a concussion, or being burned.

Compounding the potential danger is the fact that it is not unusual for the occupants of a home to store flammable, toxic substances in containers near combustion appliances. These substances can ignite, causing a fire to spread rapidly and exposing the inspector to toxic materials and smoke.

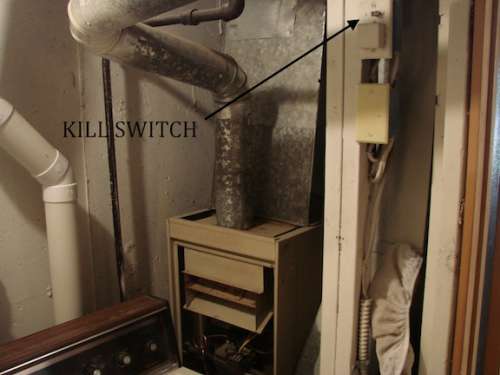

Inspectors should allow gas to flow no longer than 10 seconds without ignition before shutting off the appliance with the electric kill switch. Once the electrical supply is shut off, the gas supply should be shut off. If the appliance has no kill switch (as water heaters typically do not), or if the switch is inaccessible or hidden, the inspector should shut off the flow of gas at the in-line valve located in the fuel pipe next to the appliance. Gas can often be shut off at a dial on the thermocouple. Inspectors should use whatever shut-off method is safest and fastest.

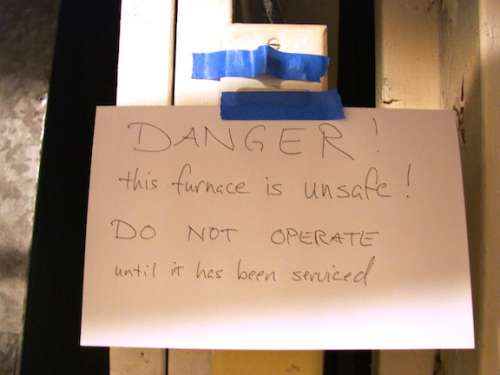

After shutting down the appliance, the inspector should tag the appliance with a note stating that the appliance has been shut down for safety reasons and should not be operated until it has been certified by a qualified HVAC contractor or technician.

Here is an eyewitness description of an actual incident with a furnace:

“Strong sewer gas odor from a sewage ejector pump with a rusty lid located in the floor about 6 feet away from a gas-fired furnace masked the smell of natural gas leaking from the furnace. A tag on the furnace stated that it had been certified by a local HVAC contractor just the day before. I turned up the thermostat, went back into the basement, and flipped on the kill switch, and there was a quick flash as gas in the air ignited.

“I shut the furnace off using the kill switch and the gas shut-off valve, taped the switch to the “off” position, and left a note taped over the switch. Apparently, because the note didn’t look official enough and the furnace had been inspected recently, upon arriving home, the occupant removed the note and the tape and turned the furnace back on.”

Because the explosion was immediate upon turning on power to the furnace, this incident was probably not due to pre-ignition but from a leak from a gas line, possibly combined with sewer gas accumulation in the mechanical room, which measured approximately 8 feet by 8 feet.

To avoid a similar situation, inspectors should carry with them official-looking notices, preferably with a red background. Before leaving the inspection, inspectors should do their best to notify all parties involved in the transaction about the problem, including the buyer and their agent, and the seller and their agent.

Here is an eyewitness account of pre-ignition with a boiler:

“I was present when an HVAC technician was testing an older gas-fired boiler. srchough ignition was delayed for approximately 40 to 50 seconds, the technician turned to walk out of the basement mechanical room but didn’t shut down the boiler. As he opened the door and began to walk through the doorway, the gas ignited. The resulting explosion blew the front cabinet cover off with great force, bouncing it off the side of the open door opposite the technician. Both our ears were ringing, the air was filled with dust and small bits of paper, which were floating slowly down toward the floor. The sheet metal cover measured about 24 inches by 30 inches and definitely had the power to injure anyone it hit.”

When possible, shut off the power first.

To avoid such dangers from pre-ignition, whenever possible, inspectors should shut off power to the appliance before turning up the thermostat. This is not always possible because with some thermostats, shutting off power to the appliance also shuts off power to the thermostat. When this is the case, the inspector should be diligent in proceeding to the appliance directly after turning up the thermostat.