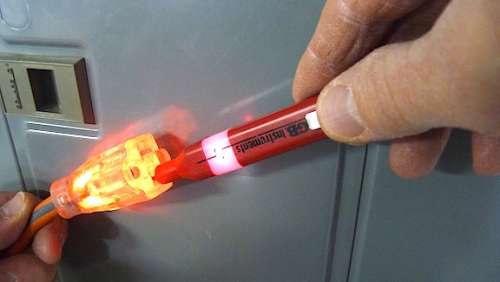

Using a Voltage Detector

The first exposure to potential danger comes from coming into contact with the metal panel, and they are all metal. It is possible for an energized conductor inside the panel to come into contact with the metal box so that the entire panel becomes energized. When this is the case, the panel’s exterior surface becomes hazardous to touch. Before touching a panel, an inspector should first test it with a voltage detector. These devices are inexpensive, small enough to carry conveniently, and easy to use.

You may hear them called by a variety of names, such as a voltage sensor or sniffer, or a tic tracer. These devices can be used to determine whether the surface of an electrical panel is energized.

Voltage detectors should always be checked with known live voltage when beginning an inspection. Without first confirming that the detector is working, an inspector may fail to detect an energized panel. Some types of voltage detectors will not work properly unless the person holding it is reasonably well-grounded. If the detector is tested while the inspector is well-grounded but, for some reason, when testing the electrical panel, the inspector is suddenly not well-grounded (such as when he’s wearing rubber-soled shoes or standing on a rubber mat), the detector may fail to detect the voltage present on the surface of the panel.

Upon finding an energized panel, the inspector should abandon the idea of inspecting the panel, post a warning tag in a conspicuous location nearby, and do his best to warn all those involved in the transaction as soon as possible that a dangerous condition exists, and recommend both in the written report and verbally that the condition be corrected immediately.